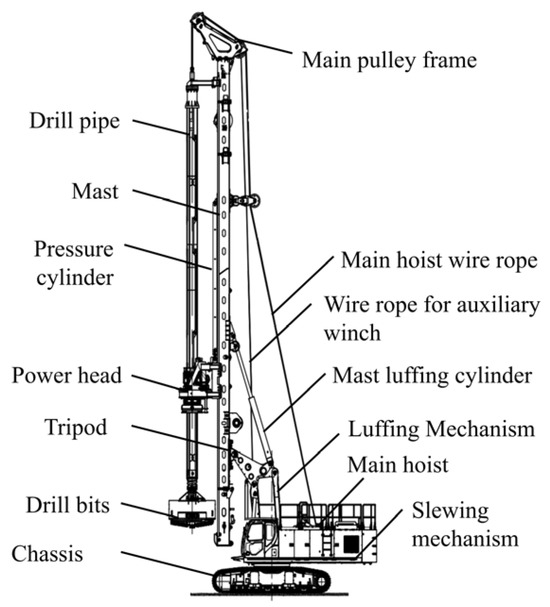

Understanding the key components of a rotary drilling rig is crucial for anyone involved in foundation piling and deep drilling operations. These powerful and complex machines are designed to bore into the earth efficiently, with each component playing a vital role in the overall drilling process.

1. The Mast

The mast is the primary structural element of a rotary drilling rig. Constructed from high-strength steel, it provides a stable framework to support the weight of the drill string and drill bit during operations. At the top of the mast is the crown block, which contains a set of sheaves (pulleys) that guide the drilling line and help support the hoisting system.

2. The Drill String

The drill string is a crucial component responsible for transmitting torque and thrust from the rotary table to the drill bit. It consists of drill pipes, drill collars, and the drill bit itself, enabling deep penetration into the ground.

3. The Swivel

Located at the top of the drill string, the swivel allows for continuous rotation while drilling and provides a pathway for drilling fluid (mud) to enter the drill string. This component ensures smooth drilling operations and fluid circulation.

4. The Rotary Table – Components of a Rotary Drilling Rig

The rotary table is a powerful turntable that rotates the drill string and drill bit. It is powered by either an electric motor or a diesel engine and is essential for transmitting rotational energy to the drilling assembly.

5. Mud Pumps

Mud pumps are critical for circulating drilling fluid through the drill string and out of the bit. They generate the pressure needed to carry cuttings to the surface and help maintain borehole stability.

6. Power Source (Engine) – Components of a Rotary Drilling Rig

The engine or power source drives all major components of the rotary drilling rig, including the rotary table, mud pumps, and hoisting system. Power can be supplied by diesel, electricity, or natural gas, depending on the rig’s configuration.

Conclusion

Each component of a rotary drilling rig works in harmony to achieve efficient and precise drilling, especially in foundation piling applications. Proper maintenance and understanding of these components are essential for optimizing performance and ensuring safety on the job site.