Introduction

The construction industry is booming worldwide, with infrastructure expansion and urban development driving demand across emerging and developed markets alike. Central to many of these operations is the concrete mixer truck—a mobile solution for transporting and mixing concrete efficiently. For international buyers, especially those in cost-sensitive or developing regions, used concrete mixer trucks represent a pragmatic and economical alternative to new equipment. However, navigating the global market for secondhand machinery demands careful evaluation, sourcing knowledge, and an understanding of international trade logistics.

Understanding the Global Demand for Used Concrete Mixer Trucks

The growing appetite for used concrete mixer trucks is a reflection of the construction sector’s continuous push for efficiency at reduced costs. In countries across Africa, Southeast Asia, the Middle East, and Latin America, infrastructure development is often constrained by tight budgets. Used equipment offers a means to leap forward technologically without incurring the steep depreciation of brand-new machinery. Additionally, the robust build quality of many top-tier brands means that even after years of service, these trucks often retain operational integrity—making them attractive assets on the secondary market.

Why Buying Used Makes Sense for International Buyers

Purchasing a used concrete mixer truck can yield significant savings, sometimes up to 50% or more off the original price. For international buyers, this allows for a larger fleet or better allocation of resources toward other critical areas like spare parts, labor, or logistics. Moreover, the depreciation curve flattens considerably after the first few years, meaning that used trucks retain more of their resale value in proportion to cost. Furthermore, the availability of global logistics solutions and digital marketplaces has made it easier than ever to access a wide inventory across borders, unlocking opportunities to find equipment tailored to regional construction needs.

Key Factors to Consider Before Purchasing

Assessing Your Project Needs and Volume Requirements

The first step in the decision-making process involves understanding the scope and scale of your construction projects. Will the mixer be used for small-scale urban development or large-scale highway construction? Consider the average concrete output per day, terrain conditions, and job site accessibility. These factors directly influence the type, size, and mobility requirements of the mixer truck.

Choosing the Right Drum Capacity and Mixer Type

Drum capacity typically ranges from 3 to 14 cubic meters. While smaller drums are ideal for short-distance, urban use, larger capacities are preferable for bulk concrete delivery on larger sites. Beyond size, buyers must also choose between front-discharge and rear-discharge trucks. Front-discharge mixers offer better maneuverability and visibility, whereas rear-discharge mixers are often simpler and easier to maintain in challenging environments.

Evaluating Brand Reputation and Model Durability

Reputable manufacturers such as SANY, ZOOMLION, MACK, HOWO, Mercedes-Benz, Isuzu have earned trust through durability, part availability, and long-term support. Certain models are known for specific advantages, like fuel economy or rugged performance under tough conditions. It’s wise to conduct research on how these brands perform in your local environment, particularly in terms of after-sales service and part accessibility.

Considering Fuel Efficiency and Emission Standards

Fuel consumption is a long-term cost often overlooked in initial purchases. Opting for a truck with a more efficient engine can result in substantial operational savings. Also, be sure to verify if the truck adheres to your country’s emission standards. Some regions restrict the import of vehicles that don’t meet certain environmental regulations, which could lead to fines or import rejection.

Where to Source Reliable Used Concrete Mixer Trucks

Trusted Online Marketplaces and Export Platforms

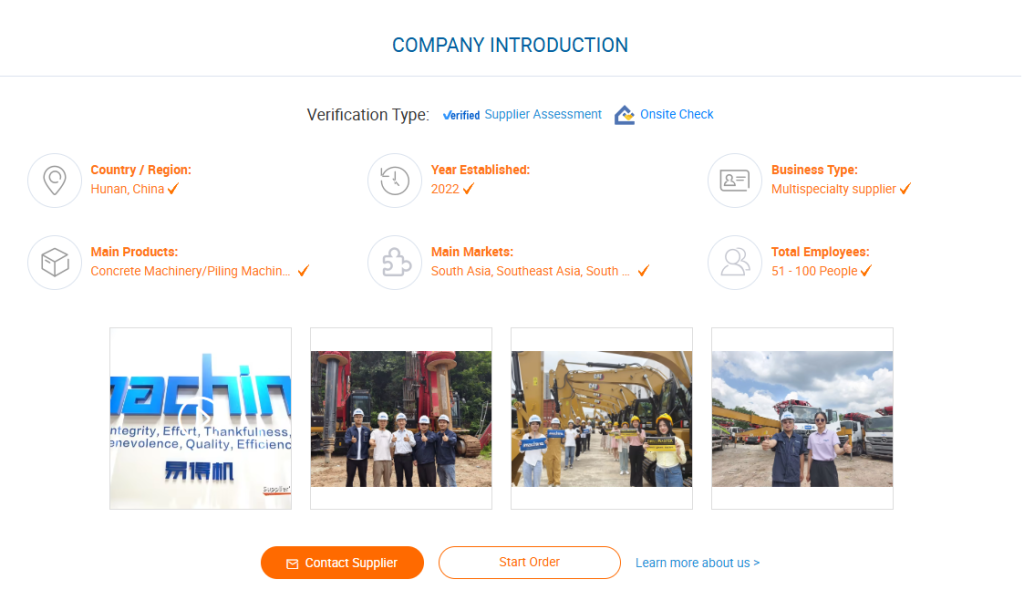

Global B2B platforms like Alibaba, Mascus, and MachineryTrader host thousands of used mixer listings from around the world. These platforms often feature seller ratings, buyer protection options, and verification tools. Look for suppliers with high transaction volumes, professional certifications, and transparent product descriptions that include maintenance history and usage details.

Working with Verified Dealers and Equipment Resellers

Partnering with a professional dealer can significantly reduce risks. Verified resellers typically conduct preliminary inspections, offer repair services, and sometimes provide limited warranties. Building relationships with experienced dealers also opens doors for long-term cooperation, easier sourcing of spare parts, and favorable pricing on future purchases.

Trade Shows and Auctions: Opportunities and Risks

Attending international machinery expos or industry-specific trade shows can yield firsthand exposure to available stock. Auctions, both online and offline, can offer attractive pricing, but they come with risks. Without proper inspection, buyers may inherit hidden defects. Always confirm the possibility of a pre-bid inspection and review the auction’s terms of sale carefully.

Inspection Checklist for Used Concrete Mixer Trucks

Engine Performance and Maintenance History

Inspect the engine for any unusual noise, smoke, or sluggish startup. Ask for service logs and oil change records. A well-maintained engine not only ensures reliability but also signals responsible ownership. Check for any signs of oil leaks or irregular engine behavior under load.

Drum Condition, Rotation Mechanism and Hydraulic System

The drum is the centerpiece of any mixer truck. Ensure the internal blades are intact and the rotation mechanism operates smoothly. Any delays, noises, or resistance may indicate wear. Hydraulic pumps and hoses should be leak-free, responsive, and not show signs of extensive corrosion or degradation.

Tires, Chassis Integrity and Frame Rust Inspection

Tires should have even tread wear and be free of cracks or bulges. Examine the chassis for structural integrity—look out for weld repairs, rusted sections, or bent framing. Trucks used in coastal or high-humidity environments are especially prone to corrosion, which can compromise structural safety.

Cab Functionality: Controls, Electronics and Comfort

The driver’s cabin should be ergonomically sound and fully functional. Inspect dashboards, levers, and control panels. A malfunctioning gauge or switch could indicate larger electrical issues. Comfort is also key—an uncomfortable operator cabin can lead to lower productivity and higher turnover rates.

Import Regulations and Documentation for International Buyers

Key Export-Import Documents You Must Prepare

Typical documents include the bill of lading, commercial invoice, certificate of origin, and export inspection certificate. Some countries may also require fumigation certificates or specific technical compliance sheets. Ensure all documentation matches the truck’s specifications to avoid customs delays.

Understanding Customs Duties, Taxes and Compliance Rules

Customs charges vary significantly depending on country and vehicle class. Investigate applicable import duties, VAT, and any port-handling charges. Non-compliance or misclassification can result in hefty fines or even seizure. Work with local customs agents or import consultants to ensure accuracy.

Country-Specific Regulations for Heavy Machinery Import

Some regions enforce age restrictions on imported vehicles or require emission certification and safety inspections post-arrival. Knowing these in advance allows you to filter out incompatible listings and avoid post-purchase regret. Verify these requirements directly from official trade or customs websites.

Tips for a Smooth International Purchase and Shipping

Choosing Between FOB, CIF and Other Shipping Terms

Understanding Incoterms is crucial. FOB (Free on Board) places the responsibility on the buyer after the truck is loaded at the port. CIF (Cost, Insurance, and Freight) includes shipping and insurance in the seller’s price. The choice depends on your comfort level with risk and local logistics capabilities.

Selecting a Reliable Freight Forwarder

A seasoned freight forwarder can handle everything from inland transport to port clearance. Look for providers with experience in heavy machinery and a global network. Check online reviews and industry certifications like FIATA membership to ensure professionalism.

Final Checklist Before Shipment and Delivery Confirmation

Before finalizing the shipment, confirm all parts and documents are in order. Ensure the truck has been cleaned to avoid quarantine issues. Request photos of the loaded container or flatbed before departure. Upon arrival, conduct a thorough inspection before releasing payment or confirming receipt.

Used concrete mixer trucks can offer tremendous value for international buyers if sourced wisely and inspected thoroughly. With proper due diligence and a structured purchasing process, buyers can secure reliable equipment that supports long-term operational success.