CFA piles and FDP piles are two widely used foundation solutions in deep foundation engineering. While both rely on advanced piling equipment, the rotary drilling rig plays a central role in their construction. Understanding the differences between these pile types helps engineers, contractors, and project owners make informed choices for cost efficiency, safety, and performance.

What is a CFA Pile for Rotary Drilling Rig?

CFA (Continuous Flight Auger) Explained

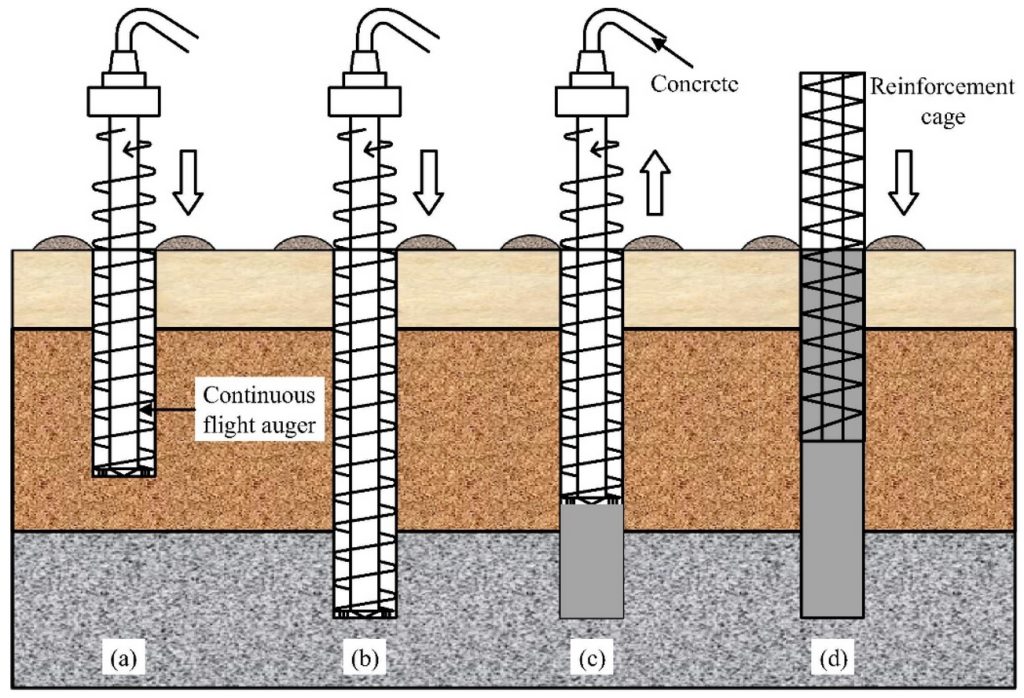

A CFA pile uses a rotary drilling rig with a continuous flight auger. The rig drills into the soil with a spiral auger until it reaches the target depth. Workers pump concrete through the hollow stem of the auger while they gradually withdraw it. Finally, they insert a reinforcement cage to complete the pile.

This technique is widely used for:

- CFA pile foundations with rotary drilling rigs

- Projects requiring fast drilling in soft to medium soils

- Situations where minimal noise and vibration are critical

What is an FDP Pile?

FDP (Full Displacement Pile) Explained

An FDP pile uses a rotary drilling rig with a displacement auger. Unlike CFA piles, this method does not excavate soil. Instead, the auger pushes the soil laterally and compacts the surrounding ground. As the crew withdraws the auger, they inject concrete to form the pile and then place a reinforcement cage.

FDP piles are commonly applied in:

- FDP pile foundations using rotary drilling rigs

- Dense soil conditions requiring strong compaction

- Projects in environmentally sensitive areas where zero excavation is preferred

Key Differences Between CFA and FDP Piles on Rotary Drilling Rig

1. Construction Principle

- CFA Pile: Uses a soil-removing auger. Soil is excavated and transported out.

- FDP Pile: Uses a displacement auger. Soil is compacted, not removed.

Core difference: CFA = soil-breaking, FDP = soil-squeezing.

2. Stratum Disturbance

- CFA piles may destabilize soft soils, risking hole collapse.

- FDP piles cause minimal disturbance and improve soil density.

3. Environmental Performance

- CFA generates drilling waste and requires disposal.

- FDP is a zero-excavation method, cleaner and more sustainable.

4. Bearing Capacity of CFA/FDA piles Rotary Drilling Rig

- CFA piles rely on bond strength between soil and concrete.

- FDP piles achieve 15–30% higher bearing capacity due to soil compaction.

5. Equipment & Technical Requirements

Most rotary drilling rigs for CFA piles are standard and widely available. FDP piles, however, require special displacement tools and advanced rig control systems, making them more technically demanding.

6. Noise & Vibration

- CFA piles: Low noise, minimal vibration.

- FDP piles: Even lower noise and vibration, suitable near schools, hospitals, and heritage sites.

7. Cost Analysis

- CFA piles: Lower equipment costs and widely accessible technology.

- FDP piles: Higher upfront costs but long-term savings due to improved performance and fewer piles needed.

CFA vs FDP Piles: Comparison Table

| Factor | CFA Pile | FDP Pile |

|---|---|---|

| Excavation | Soil removed | Zero excavation |

| Environmental impact | More waste | Cleaner, eco-friendly |

| Bearing capacity | Good | Higher (15–30% more) |

| Construction speed | Fast | Moderate |

| Cost | Lower | Higher (but efficient long-term) |

| Equipment | Standard rotary drilling rig | Specialized displacement rig |

How to Choose Between CFA and FDP Piles of Rotary Drilling Rig

When selecting the right pile type, consider:

- Soil conditions: Loose or waterlogged soils → CFA; dense soils → FDP.

- Environmental restrictions: FDP piles are ideal where zero-excavation and low vibration are required.

- Project scale and budget: CFA is cost-effective for smaller budgets; FDP suits projects prioritizing durability and sustainability.

The Role of Rotary Drilling Rigs in Pile Foundations

Whether constructing CFA pile foundations or FDP pile foundations, the rotary drilling rig is the core equipment. Its flexibility allows contractors to switch between augers and adapt to different soil conditions, making it an indispensable machine for modern foundation engineering.

Both CFA piles and FDP piles have their advantages. CFA is efficient and cost-effective, while FDP offers higher performance and environmental benefits. Choosing the right method depends on soil type, project requirements, and budget. Regardless of the choice, the rotary drilling rig remains the essential tool that powers both techniques.